Contract works

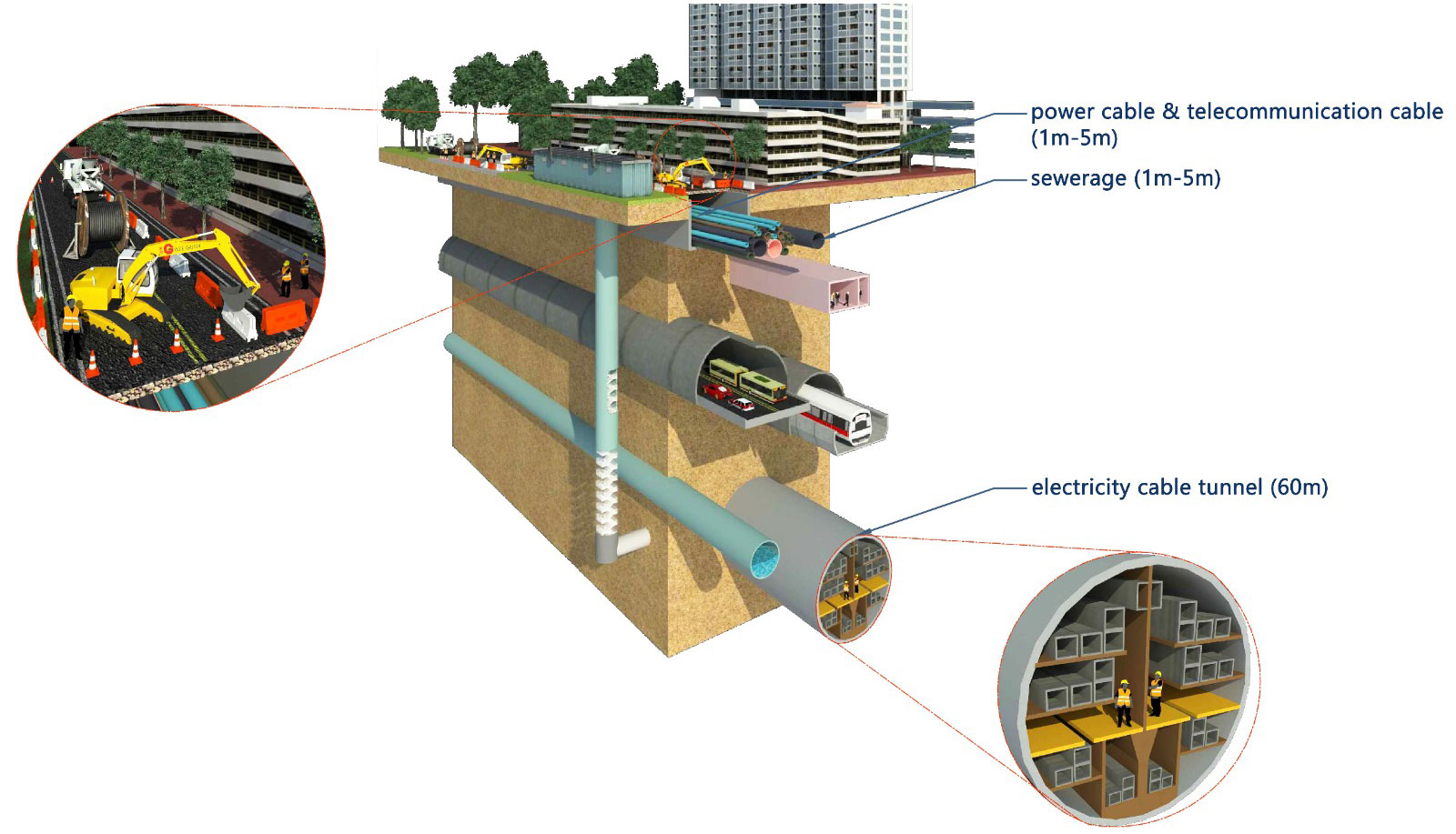

We install power cables (for both transmission and distribution of electricity), auxiliary cables and accessories, telecommunication (including ISP works and OSP works) and fibre optic network as well as sewerage pipelines by applying methods such as (i) open cut excavation method; or (ii) trenchless methods, namely cable tunnel installation, pipe jacking, horizontal directional drilling and guided auger boring method.

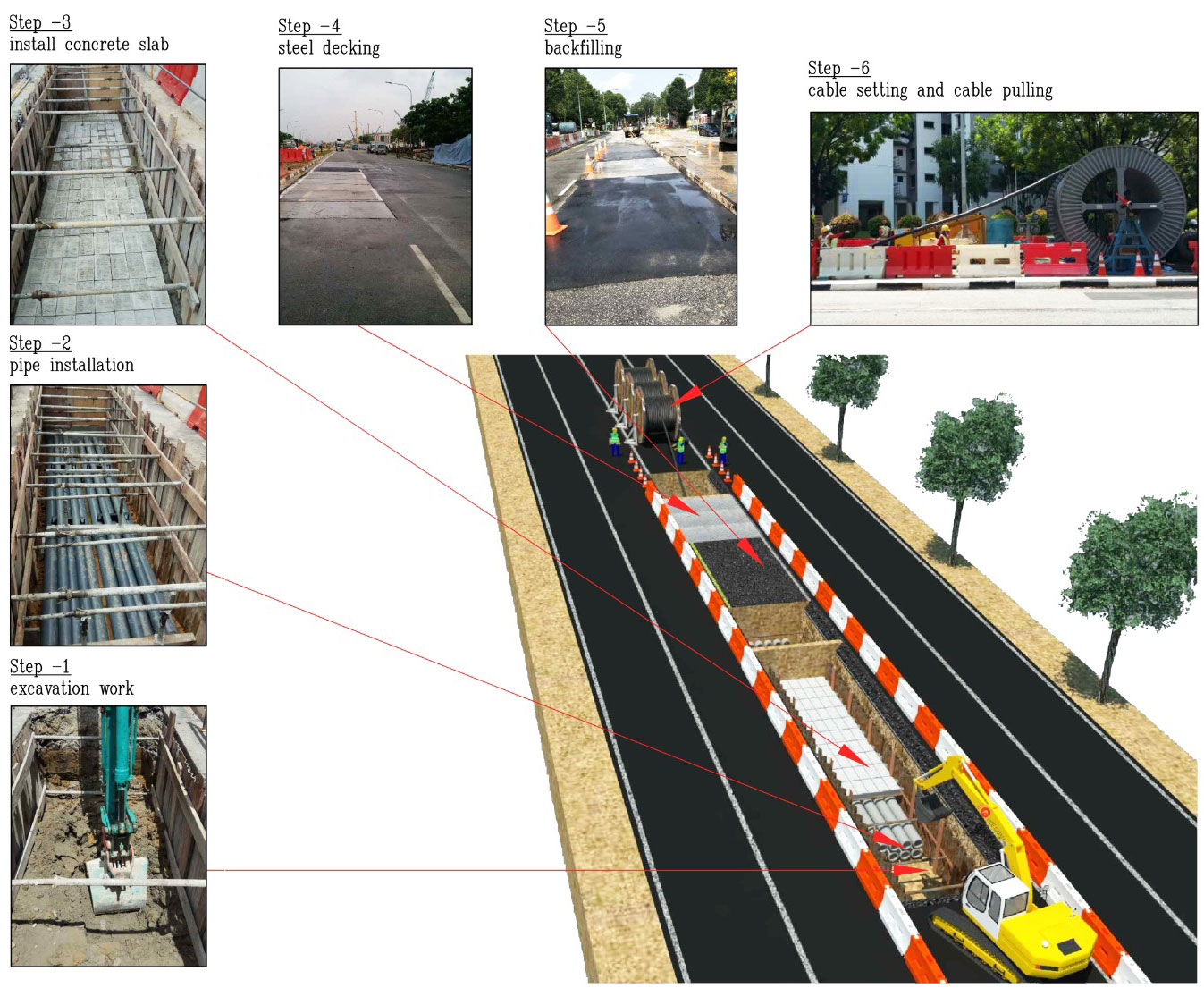

Open cut excavation method

Open cut excavation is the use of open trench or excavation along the pipeline route for the installation process. We apply open cut excavation generally for installation works of power cables, and telecommunication and fibre optic networks approximately one to four metre(s) beneath the ground level. Our major tasks involve digging and excavating a trench, placing the utilities pipes, installing concrete slab and/or steel decking for the reinforcement of the trench structure, backfilling of the trench, cable setting and cable pulling.

Trenchless methods

When applying trenchless methods, the need for excavating the ground for the underground utilities pipeline route would generally be minimised. We generally apply trenchless methods, depending on the circumstances of the work site, for installation works of power cables, telecommunication and fibre optic networks or sewerage pipelines approximately four metres or more beneath the ground level.

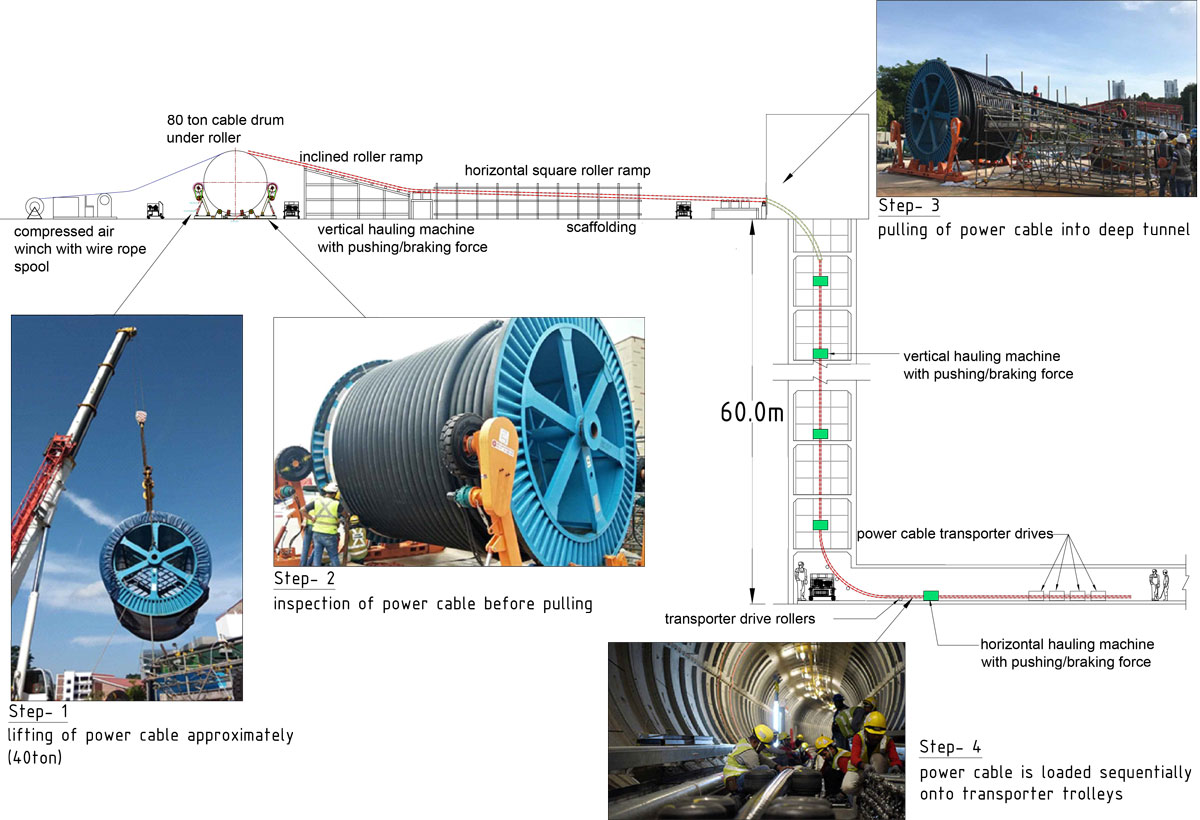

We install high-voltage electricity cables along tunnel sections where the majority of such tunnel sections are buried approximately 60 metres beneath the ground level. Our main tasks involved in a typical cable tunnel installation project include not only the installation of the high voltage electricity cables, but also the installation of supporting parts to the power cables.

The following diagram illustrates the power cable installation process (i) from spooling out a cable from ground level to pulling such power cable to entering the underground tunnel; (ii) from vertically pulling such cable from the tunnel entrance to the designated underground tunnel section of approximately 60 metres underground.

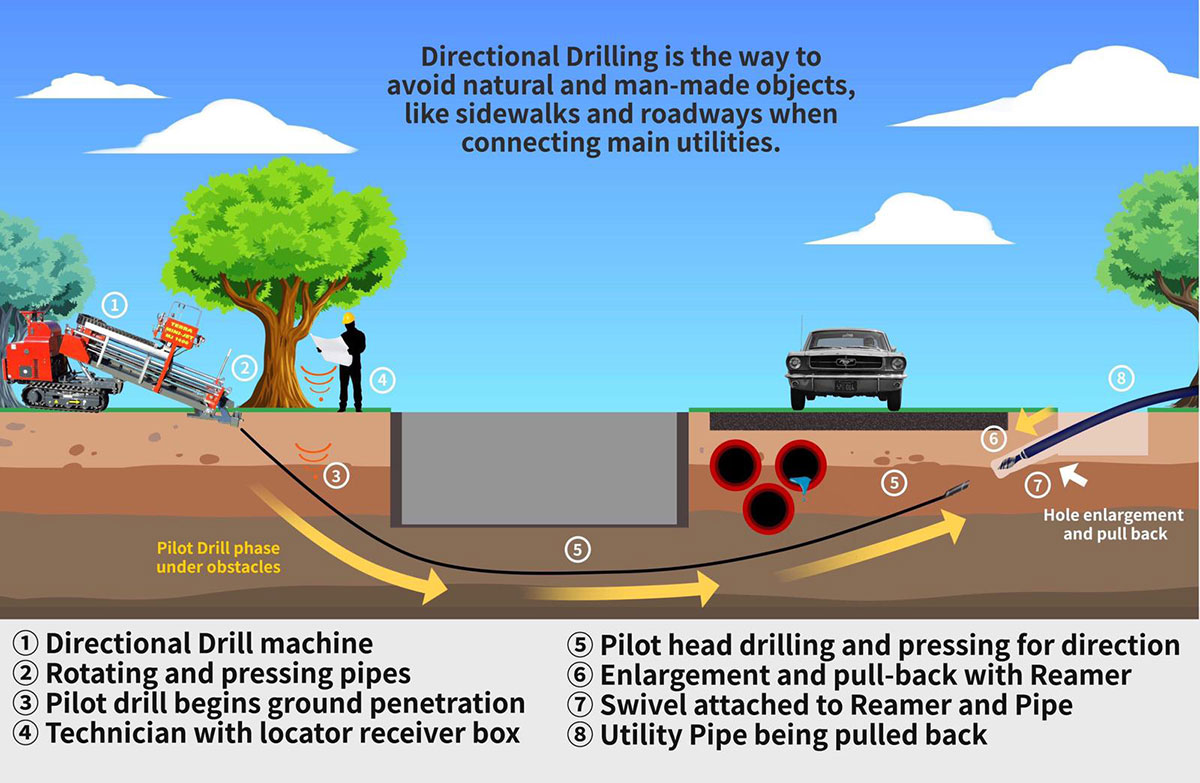

For installation works of power cables, and telecommunication and fibre optic networks approximately four metres or more beneath the ground level, we generally apply horizontal directional drilling method. As illustrated in the following diagram, our HDD method is a way to avoid natural and man-made objects such as sidewalks and roadways when connecting main utilities:

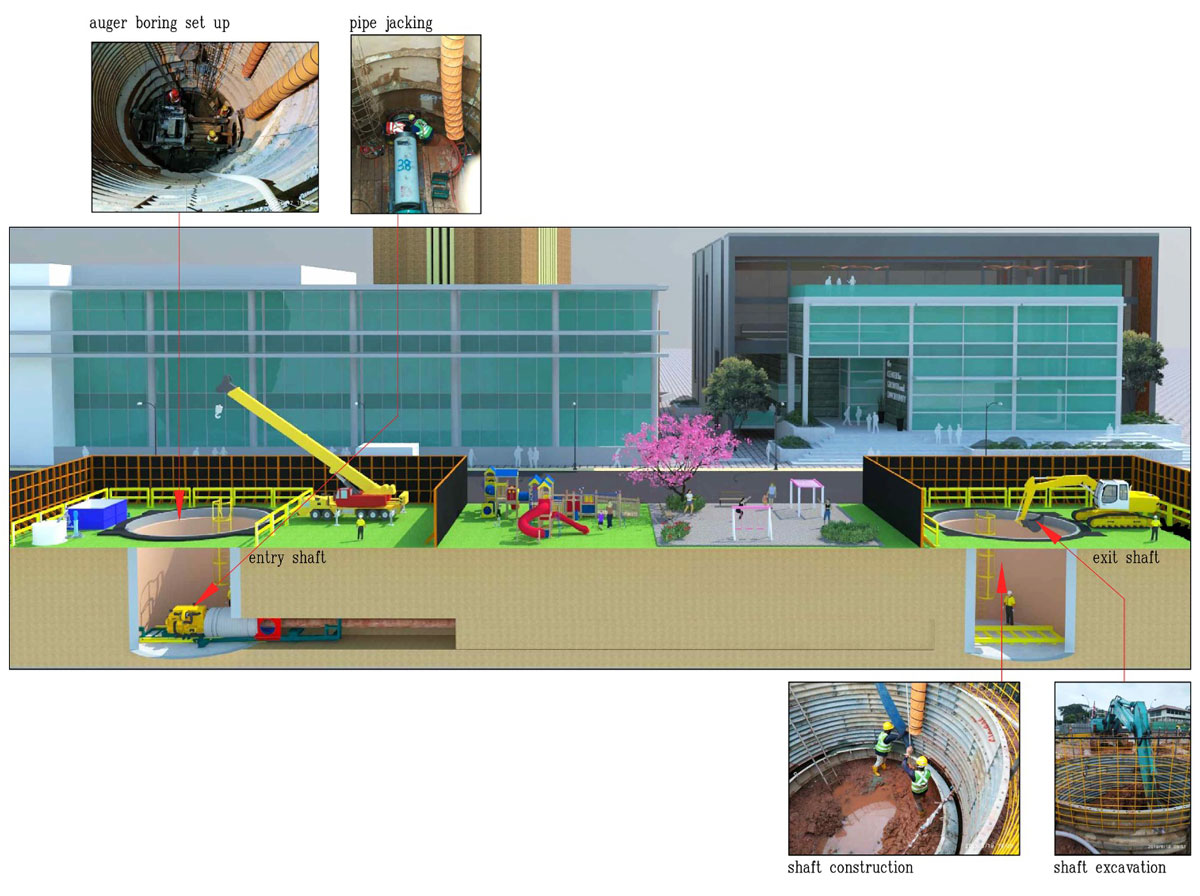

Pipe jacking involves the boring of a tunnel for the installation of pipes, by a tunnelling shield (generally by a fully automatic mechanised tunnelling machine inside a hand shield) from a launch shaft at one end towards a reception shaft at another end. The shield is jacked forward incrementally by hydraulic jacks at the launch shaft. As the shield advances, jacking pipes are inserted behind the shield one by one and the whole string is jacked forward. When the tunnelling shield reaches the reception shaft at another end, it is removed and the pipe installation is completed.

Similar to pipe jacking method, guided auger boring method generally involves cutting out a bore hole which size shall be just sufficiently enough for pushing or pulling through the pipelines for installation. The cables are pushed or pulled into the bore hole at the same time when boring the bore hole.

The diagram below depicts the processes of pipe jacking and auger boring: